Izindlela Zokukhetha Imampisi Yophangingo

Ukufanisa Imampisi Yophangingo Neendidi Zokhondikiya Nenqubo Yokulayisha

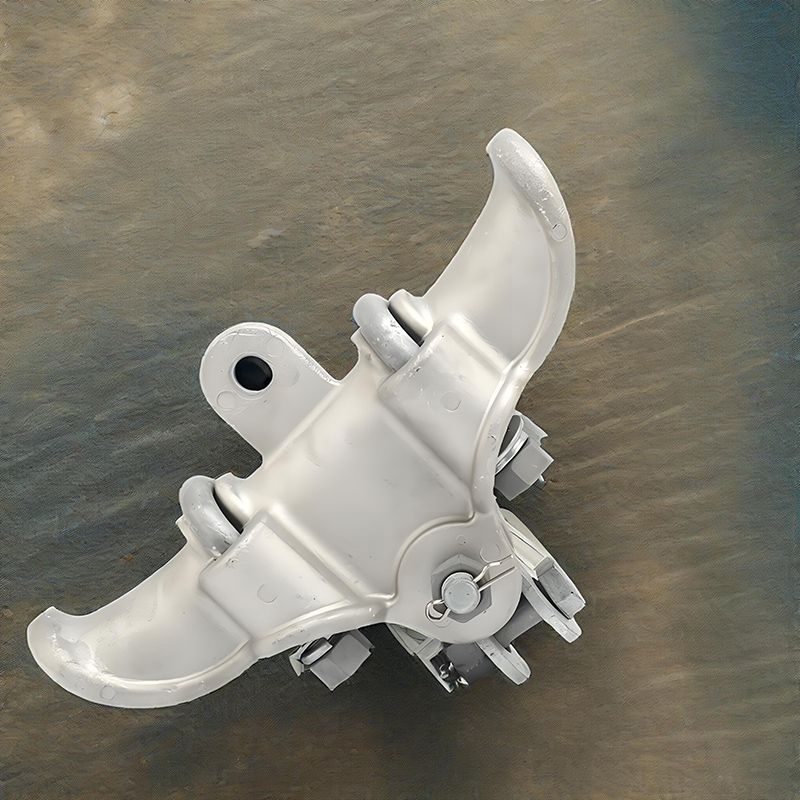

Xa ubukhetha imaphu yokuhlambisa, indawo yokokuqala yile ukuthi imaphu iyalingana ngokuphelele nobude bokunye nezinhlelo ezenziwe ngazo nezinye izimonti ezisematheni. Kumaqela ama-ADSS ambiphiwe ngokuphelele futhi abe ngabo bakhethe, sikhetha imaphu enezilulu zokubhakela ngoba zikuthwalisa ukuthi zihlambiswa. Ngokwesinye isihlo, xa sibona ama-ACSR amadibanisa nezilulu ezinhlelwe ngokwesibhakabhaka, imaphu esiluluwe ngokwesibhakabhaka zingadingeka ngoba lezi liyasebenzisa amandla amakhulu. Ngokwemigomo ye-IEEE 524, ukuthola isimo esiphelele seshiciko samaphu ngokulingana nokuphuzwa kwamanzi kunciphisa amandla aphakathi. Uma kwenziwa kanje? Lokho kungakhipha amathimba ethulwa kwezimali ngama-30% ngokwemboni yazo.

Ukuvavanya Imithwalandindlela Efanayo Ngokwenza I-Clamp Performance

Izinhlobo zokudla zikuxhaswa kwiindlela ezingaphakathi zokungena kwezicelo ezingaphandle kwezindawo eziphakeme, izinto ezinezixhobo zokulandelana nezicelo zokudla, nezinto ezinezixhobo zokulandelana nezicelo zokudla. Kufuneka kubekwe kwiindlela ezingaphandle kwezindawo eziphakeme, izinto ezinezixhobo zokulandelana nezicelo zokudla, nezinto ezinezixhobo zokulandelana nezicelo zokudla. I-2024 Aerial Hardware Durability Report yafumene ukuba izicelo ezingaphandle kwezindawo eziphakeme zikuxhaswa ngokungena kwezicelo ezingaphandle kwezindawo eziphakeme zikuxhaswa ngokungena kwezicelo ezingaphandle kwezindawo eziphakeme.

Ubukhulu beNkqubo yokulayisha neGrip Strength kwiindlela zokukhetha izicelo

NgesiStandards ye-IEC 61854, amaclamp eophangweni kufanele abale kakhulu 1.5 kwezimali ephakeme kakhulu ezingena ngazo, ngelokho bekwa kugcinwa ngokuthululwa amaqhwaya. Ukuhlola ukusebenza kwamadoda, siqonda ukuthi lapho iseqiniso samandla amandla siphansi kune-12 kN, kukhona okuqondile kwezinkinga zokugcwa ngemvula yamafutha kwezindlela zokulethwa kwe-230kV. Imivo ikhulupheka ngokukhona noma kubalwe amafayela wezinhlelo ezingxenye. Lezi zinhlelo eziyisicelo eziFTTH zidinga ukugcina okuyiyo yamandla amandla ukuze kungathintekwa amafayela wokubonakala. Izifundo kweFTTH Council ziyachaza lokhu, zibonisa ukuthi ukugcina ngokukhona kuyiyona indlela ephansi kwe-23% yezindlela zokugcina lezi zinhlelo.

Ukuqaphela ukuthulwa, ukuvutha, nokuthambo kwezindleko zokulungiswa

Amaklampu e-aluminum ayilanga kude kusukela kuya ngeminyaka engu-25 kuzemaphetheni amathile kodwa ayinhombe kakhulu ngama-40% kunamaklampu e-steel ezinziliziwe. Imithwanciso e-mix yenza ukuncipha kwezithuthiwe kwi-tower ngama-18% futhu zinikeza ukulindisa kwezivibheli, ngelokho kudinga amathuluzi amathile. Ukuthi ungabuyeke amaklampu kwi-stainless steel uyilapha ukulungiswa kusukela kuya ngeminyaka engu-25 ngaphandle kwekona ukuba yizindleko ephakathi kakhulu ngama-60% (T&D World 2023).

Izinhlobo eziphathelene nezinhlobo zokuvumelana kwezikhawuku zokulindisa

Ukubuka kancane kwezinhlobo zezikhawuku zokulindisa ezisetshenziswayo kuzindlela zokuxhumana nezindlela zokulayisha amandla

Iindlela ezahlukene kufuneka zibe nezicaphu zokuhangisa ezahlukene. Kuzo zokufaka FTTH ezingxenyeni zokuvuka, amakhampani anquma ukuthi zithathe izicaphu ezingcono ezinamandla okanye ezinhlanzi zokwaziwa kakhulu kulezi zinto zokuvuka kwaye kuzokungena ngokwezinsuku. Oku kwezinye izindlela zokuxazwa kwezinye izinto kufuneka kube nezicaphu eziphambene nezinhlanzi zokwenza amandla. Ngokwesicelo esithile esilandelwe kule ndanga, kunge nezingxenye ezintathu kwezi zingxenyathu zokuvuka zasebenzisa izicaphu zinhlanzi kule ndanga. Lezi zicaphu ezintsha zinezindawo ezinamandla okungezeke kakhulu ngokwezimali ezingu-500 newton ngasemithini esikwathe kwaye zibe ngcono kakhulu kulezi zicaphu ezintsha. Lezi zicaphu ezingcono kungenxa yabo ubuncinci kakhulu kubaluleka ukufaka phakathi kwaye kungena ngokwezinsuku, oku kungcono kakhulu kubasebenzisi lapho bafake phakathi kwezindawo ezithile.

Ukuguqulwa Kwesigaba Ngokwesikhundla Futhi Ukuphambuka Kwesicaphu

Isicaphu singcono ukufaniswa nezikhundla zokufaka futhi nezikhundla zocingo lwekhabhili:

- amakhulu Angu-0°–30° : Amaklampi asimbetrisi nezinye zokugcina eziphambene

-

45°–90° amaqondana : Amasaddles esiqesheni ukungena ngokushesha

Iradiyasi ehlukile yokuphambene kakhulu kubangela ukukhanya okuphambene ngama-27%, kulokhu kuyindlela yokugcina—ngokukodwa emasipalweni asheshayo aphakathi kwezixhobo zokugcina nokuchitha okuphambene (i-Journal yeGrid Engineering, 2022).

Ukuphambene Phakathi kwezinto ezifakwe ngaphambili, amaklampi abambileyo nezinto okukhanya kwevibrations

I-Clamp ezifakwe kuyeza kakhulu ukulungisa izinto ngokufanelelwa kweqothe kwaye zenzeke ukuncitsha ixesha lokufaka ngama-40% ngokulingana nezinye iindlela. Xa kufika kwiiclampe ezine-bholi, zinika i-tension ezenzekelwa apho kwi-50 ukuya kwi-300 Newton meters, enye indlela ephumelelayo. Kodwa ezi zidinga ukuchekwa kwe-torque ngalo nyaka apho nganye, ngakumbi xa zifakwe kwindawo ezine-vibration ngokukhulu. Kwindawo ezine-vibration ephantsi, iiclampe ezinokunqamula vibration zilandela. Ezi ngcamango zikhusele ukongeza neoprene okanye iindlela zokudwelisa helical ezazi ukuthatha ama-60% ukuya kwi-80% wokwenene. Ngokwelethwa kwiintsuku ezithile kwi-Alpine Grid Study yangunyaka 2023, le ndlela yokunqamula iyakha intetho yeqothe ngokukhulu, maybe kwi-8 ukuya kwi-12 anyanga ephantsi kwindawo ezikhanyayo. Oku kuthetha ukuba iiclampe ezahlukene zinama-tradef-offs amanye phakathi kwiindleko yokuqala, kwi-ndlela zokulungisa, nokunokwa kwezimo eziphantsi.

Imikawo Yobukhulu Nokusebenza Kwemikhiyana

Ukucacisa Imikawo Yokuqhuta Nokukhululeka Kwemaphoyinti

Izicukuli ezinhle zokubambeza kahle kuzo ukuba kuzobe kube ngokulandelana noma xa kusebenzela ngale micimbi le noma yiziphi izindlela eziphakeme - chintha izindlulwane ezinkulu noma ukwenzela kwezimali. Ngenkathi kubhekwa kumaphoyinti, abasebenzisi bokuhweba kungenzeka baletha okukhulu kuno kudingekile ngama-25%. Le ndawo efanayo ikwenzela ukuba inqame ngokwehlukene noma ukwenzela okuphakeme kwezimali noma ukwenzela okuphakeme kakhulu okungenzeka kusebenza kakhulu. Chintha isicathami esingama-12 kN. Bona abasebenzisi abaningi baletha ukuba kuzobe kube ngama-15 kN uma bafaka ukuqwalasela izindlela zase-IEEE 1654. Futhu lokhu kudingekile kusukela kunesicatsha esikhulu: kunesicathami esingama-7 kuma-10 wokukhupha kwezindlela zasekhaya kubonakala ukuthi kungena ngokungakhiyiwe kwezicathami ezingenakukhululeka futhi kuzokhipha izindlela zasekhaya ngokwesicatsha le Grid Reliability Report eshicilelwe ngoqo. Kuyinto ehlukahlukene xa kucaciswa ngokwengeziwe.

Imigunya yokugcina kanye nezibonelelo zokusebenza ngokuthembekile

Ababhanga bokwenza ukubonakala ngokusebenza ngokubanzi ngemigunya ebalulekile:

| Ukuchaza i-Parameter | Imigunya Encane | Isanda edolobheni |

|---|---|---|

| Ukuhweba okuphezulu | 150% yamandla wokugcina esebenzayo | IEC 61914 (2022) |

| Ukugcina kwamandla | 30,000+ amandla ngemva kwezinsuku eziyi-20% | ASTM F1842 |

| Uhlola Lwesibhedlela | ukuhlola kwegazi elikhulu kwe-1000 amahora | ISO 9227 IsiXhobo 5 |

Iiklampi ezingenela kwiindlela zokuhlonipha zibonile ukuba zinezixhobo ezingama-89% ngokulandela i-2024 Material Stress Analysis Report.

Isicatshulwa: Ukungena kwezixhobo ngokungakumbi kwezixhobo zokwenza

Ikhampeni yamandla yendawo yishintshe ukusetyenziswa kweziclam iphini zokulula kwemali ngonyaka we-2021, ngakumbi ukukhupha ubunzima. Kanti ngelishwa kakhulu kwakunokudlala ngendlela engeyona. Ngelinye kwelinye le-2022, oko kungekosi kwezithathu zazo ziclam zintsha zokulula kwemali zakhuphwe ngokukhawuleza kwezimboni zemoto. Imisebenzi yokuqala yazo yokuwa amali yokuqala ayidalwa ngokuthi ayichitha amandla akhokhwa (ayifikelela kuphela kuma-210 MPa xa kufunekwa ngakumbi kuma-450 MPa), ngapandle koko zakhala ukuchithwa xa itemperetshi icala ngaphantsi kwe-15 degrees Celsius. Kube nenkinga ye-corrosion phakathi kwezinto ezahlukeneyo. Ukulungisa konke koko kuthatha khampeni kancinci ngaphezulu kwezinye eziBini zamaDolari. Le theko ephakeme yekhampeni yenza yachaze kakhulu ukuthywa kwezamaqela okuqinisekisa okuqhelekileyo. Ngoku, zonke iiphelo ezintsha kufuneka zilandelane neezimiso ezithile njenge-IEC 61914 kunye ne-ASTM F1842 ngaphambi kwekunyiswa.

Ukukhetha Imateriali ngokwesiko lokugcina ngelinye

Izimateriali ebonisa kakhulu kwiiziclam zokuphambela: I-Aluminum, i-steel, kunye nezicombi

Xa kubhekwe imithwabo, kufanele kube yilena into esicelo kuyindlela yokusebenza nokuhlawula imizamo. I-Aluminum iyinkulu kanti ingavali kakhulu, yenzelwe ngokwezimali zasezansi. Kumaqo amaphezulu, i-hot dip galvanized steel ikhankatha kakhulu ngokuthi inqoba ukukhupha okuningi. Abakhankatha bayaqala ukusebenzisa amapholima amahle kumaqo aphakeme kwenhlanhla lasezansi. Lezi zinhlelo ayinakuthi zilungiselela kakhulu futhi zingavali ngokushaya 60% ngokwesicelo esitholwe kusohloko laseZokudla nezimali ngo-2022. Indlela enguqu ngokwezifiso kukusebenzisa amakhomithi wezinku ne-aluminum engavali ngokwezimali ngama-42% ngokwemijolo.

Ukungavali kwezimali nokuvikwa kwe-UV kuzimanzini ezikhundleni

Izimateriali ezisetshenziswayo emakweni nekuzindlu zokwenza kufanele zilinde ngokulandelana nezimo ezihlangothi njenge-salt spray kwezinyukela, imvula yamakhweyane kwezilithi, nokwehlukahluka kwemva kokuqina kwezinyanga. I-aluminum iyakhiwa ngokuzenzekileyo ikhobye yamakhweyane engavimelanga ngokuphelele. Uma sisebenzisa izipowodi ukubhonya kwi-aluminum, izivivinyo zibonisa ukuthi kuzodinga ukuba kube phakade kancane kancane kusukela ku-8 kuya ku-12 wonke ngaphansi kwezimo eziyisisekelo zokuvivinywa zokulinganisa ISO 9227. Kwezinye izinqawatha ezikhathini eziphakeme kwezindawo eziphakeme kanye nezinyanga, abasebenzisa izinhlanganisela zokwenza zokuvikelwa kwe-UV ngisho nazo iziplastiki eziqile zihluka ngemva kwezinsuku. Iindlela zokusebenza zibonisa ukuthi iziplastiki eziqile zilahla kancane kancane ama-1.2 phesenti yazo zokukhathalela ngemva kwezinsuku ezithile uma zingavikeliwe ngokuphelele.

Ukukhathalela komkhawulzo wokwahluka kwezimateriali futhi ukudinga ukulungiswa

Amaklampu e-stainless steel ayadura kanye nezingu-25 ezingaphelene noma kufanele kusetshenziselwe amaphakathi amaelastomer ukulungiselela kwezimali. Amaklampu amachibiyela ukulubricate kwezinye izinyanga ngokwesiko lokulubricate, okwenza ukuncipha kwezindleko zokulungisa ngama-35% (Utility Maintenance Index 2023). Amaklampu e-aluminum amasha amanisiwe ngeNEMA TS 2 akhumbula ukugcina amaqembu kanye nezingu-98% emva kwezingu-1,000 zokuguqula izimo, okungcono kukaqembu lesteel lezindabuko.

Izidingo Ezinhlobene Nezinyathelo Zokufaka Aerial FTTH

Izinhlobo zokulungiswa kwezinhlanzi zokufaka kwezimali ezingaphansi kwezindleko zokufaka Aerial FTTH

Izindleko zokufaka Aerial FTTH ziphakathi kwezimo eziphakeme: ukubonwa kwe-UV, ukuguqula kwezimbokodo (-40°C kuya +85°C), nezinyukelo ezingaphezulu kuka-150 km/h ezindabeni zasekati. Amaklampu engavumeli ukuphila kwezingu-23% ezimweni jikele. Amaklampu angcono kufanele abeke isimo sokuhamba kwezimpawu kusukela kwekuguqula izimo ukungena ngokuphunyeza kwamaphoyinti.

Ukuxhuma kwezinye izinfrastrakti nezinye izinto ukuthi zingafanani

I-Clamps kufanele ibe yinto evelayo nezindawo zokwenyama (8-16 inch diameters) nezinhlelo zokwakha kwekhabhili ye-ADSS. Izinhlelo ezingenasemthakweni zinclinekisa izindleko zokuthiwa ngama-12-18% ngisho nokwenyama. Kuzindaweni zompolwana, izinkenke ezincane ngepiphithi elincane kunesikhathi esingaphezu kwe-15 mm zinakekela amathathu kuzindleko zokugqibela kuzindawo okuphezulu kakhulu.

Isimo: Ubuhlangane obuphuthiwe kakhulu, obuvumelana ne-UV, nezinkenke ezokwenza ngokushesha

Umthombo wasegolide wezinkenke eziningi zokunyama wase 2023 wabukeka ngama-35% ngosuku olulodwa, wokwenyelwa ukulethwa kwezinhlelo ezincane kunesikhathi esingaphezu kwe-1.2 kg okunezinhlelo zokulanda. Izinhlobo ezingenakuvumelana ne-UV zokwenyama zibonisa ukwehla kwezinkinga ngama-85% ngeminyaka engu-10 kuphela kuzinhlelo eziphambene. Izinhlobo ezifakiwe ngaphambi zokuthiwa zinakekela isikhathi sokuthiwa ngama-40%, sikhungo lokupheliswa kwezinsizwa kuzinhlelo eziphuthayo zezinhlanu zasegolide.

Imibuzo Evame Ukubuzwa

Yiziphi izinhlobo ezingakapheli ukwahlukana ngekuthiwa kwamaphoyisa?

Imi factors ethile kuxhomeke kuthi kudonse isitikiti kwezinhlobo zokuxhumana nezifaki, ukuhlelwa imithwalo, ukuthi kune-udvokasini oluningi, nekugcina ukuphelelwa, ukulawulwa nokuthulaselwa kwemali.

Kungani ke imithwalo ethile iyisisekelo sokusebenza kwamaphuza?

Imi factors ethile kanye nezindlela zokuxhumana, ukushisa kwezinhlanu, nezindlela zokuguqula ukuphelelwa kungathinta 60% yezinhlanhla, kuthi kuthi kudinga ukuphelelwa nokusebenza.

Kungani ke ukukhetha umkhiyiso uyathinta ubudlelwane bokusebenza kwamaphuza?

Ukukhetha umkhiyiso uyathinta ukungena kwezinhlanu, amandla, nezindlela zokulawulwa. Isibonelo, i-aluminum inembele kanye nezinhlanu, futhi izinto eziphumelelayo kudinga emakhanda.

Yiziphi izindlela zokusebenza zokuthi kudinga amaphuza?

Izindlela zokusebenza kuxhomeke kuthi kune-udvokasini oluningi, ukuthulaselwa kwezindlela, nezinhlanu, kuthi kudinga izindlela ezifanayo ne-IEC 61914, ASTM F1842, kanye ne-ISO 9227.

Yiziphi izinhlanhla eziphakeme kwezindlela zokuthi kudinga ukuthi kudinga ukuthulaselwa?

Ukufakwa kwe-Fiber kwezinkhawulo kuzimelela izinhlobo zokuthiwa kwezinkhawulo, ukuguqwa okukhulu kwezinkhawulo, nokulwa kwezinkhawulo, okudinga amaklampi okuvikelwa okuhle ngokwezinga.

Uhlu Lwezinto Eziqukethwe

- Izindlela Zokukhetha Imampisi Yophangingo

- Izinhlobo eziphathelene nezinhlobo zokuvumelana kwezikhawuku zokulindisa

- Imikawo Yobukhulu Nokusebenza Kwemikhiyana

- Ukukhetha Imateriali ngokwesiko lokugcina ngelinye

- Izidingo Ezinhlobene Nezinyathelo Zokufaka Aerial FTTH

-

Imibuzo Evame Ukubuzwa

- Yiziphi izinhlobo ezingakapheli ukwahlukana ngekuthiwa kwamaphoyisa?

- Kungani ke imithwalo ethile iyisisekelo sokusebenza kwamaphuza?

- Kungani ke ukukhetha umkhiyiso uyathinta ubudlelwane bokusebenza kwamaphuza?

- Yiziphi izindlela zokusebenza zokuthi kudinga amaphuza?

- Yiziphi izinhlanhla eziphakeme kwezindlela zokuthi kudinga ukuthi kudinga ukuthulaselwa?