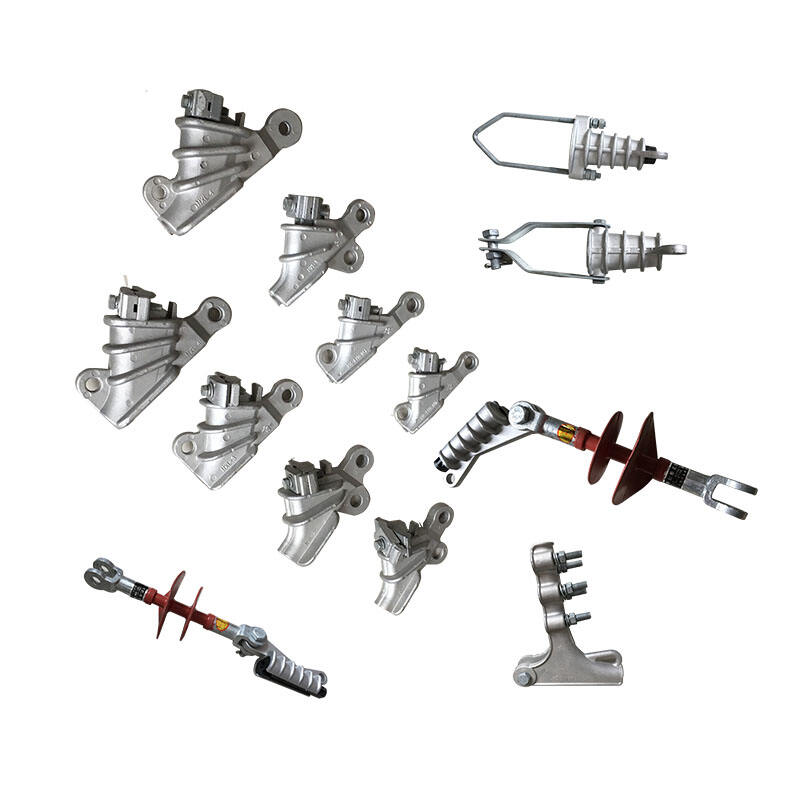

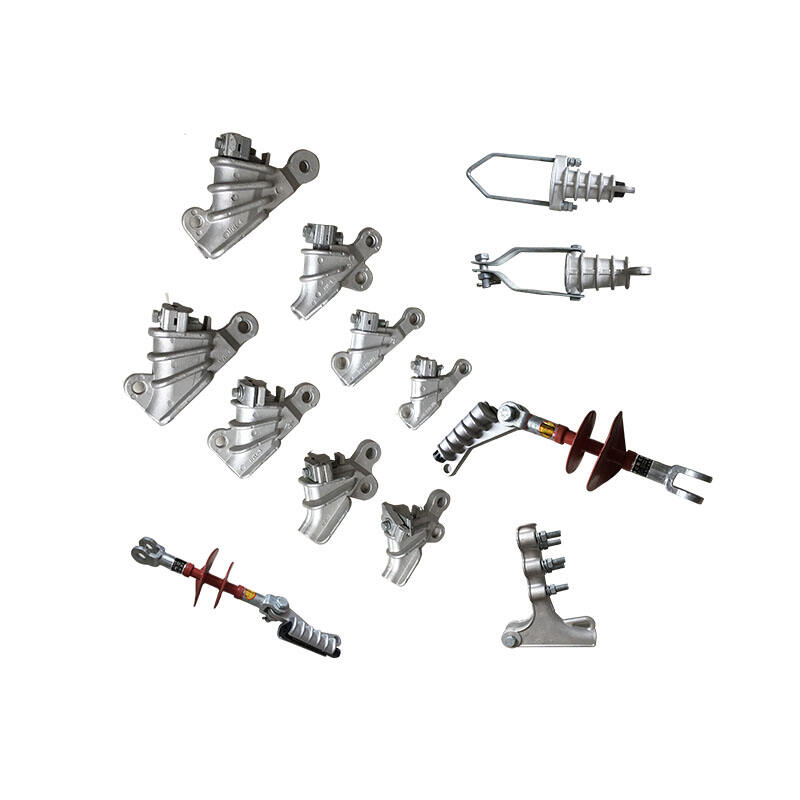

Dead end brackets are critical components in power transmission and distribution systems, providing essential support and stability for overhead lines. At Hebei Heiniu Electric Power Fittings Co., Ltd., we specialize in the manufacturing of high-quality dead end brackets that are designed to withstand harsh environmental conditions while ensuring optimal performance.Our dead end brackets are crafted using a variety of advanced manufacturing techniques, including casting, forging, and metalworking, which are complemented by rigorous testing procedures to guarantee their durability and reliability. These brackets are engineered to accommodate various cable sizes and configurations, making them versatile for a wide range of applications in the power industry.One of the standout features of our dead end brackets is their ability to effectively absorb tension and distribute loads evenly, reducing the risk of cable failure and enhancing the safety of your electrical infrastructure. Additionally, our brackets are designed with anti-corrosion treatments to extend their lifespan, ensuring that they remain functional even in challenging weather conditions.As a company committed to innovation and quality, we continuously invest in research and development to improve our products and meet the evolving needs of our customers. Our dead end brackets are not only compliant with international standards but also reflect our dedication to providing solutions that enhance the efficiency and safety of power distribution networks.